Toric Lenses

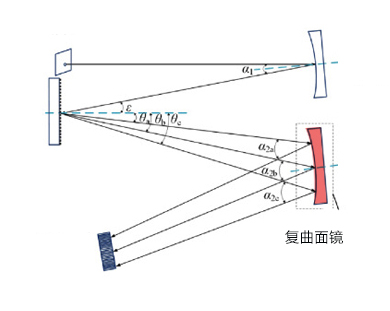

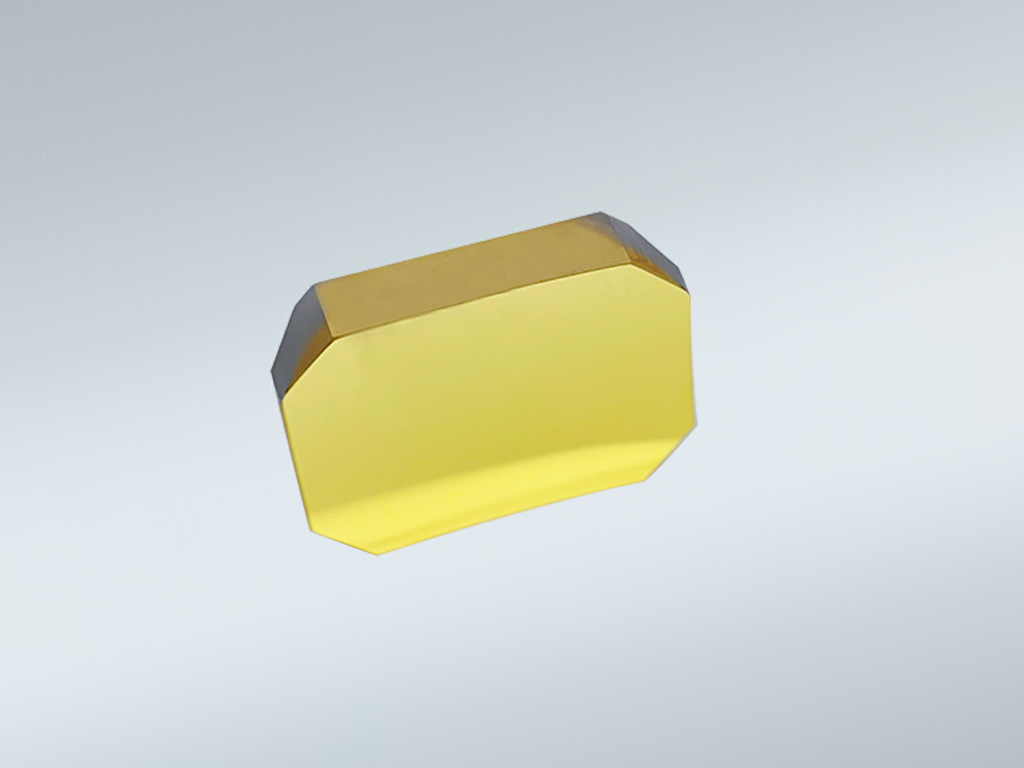

A toric surface deems as an arc rotates around an axis of another axis, it’s mostly used to replace several optical lenses to simplify the structure of the equipment and improve image quality. Unlike smooth reflector and single spherical reflector that have some problems like anamorphose by reflection, the toric lens will assist in reducing the number of optical lenses needed.

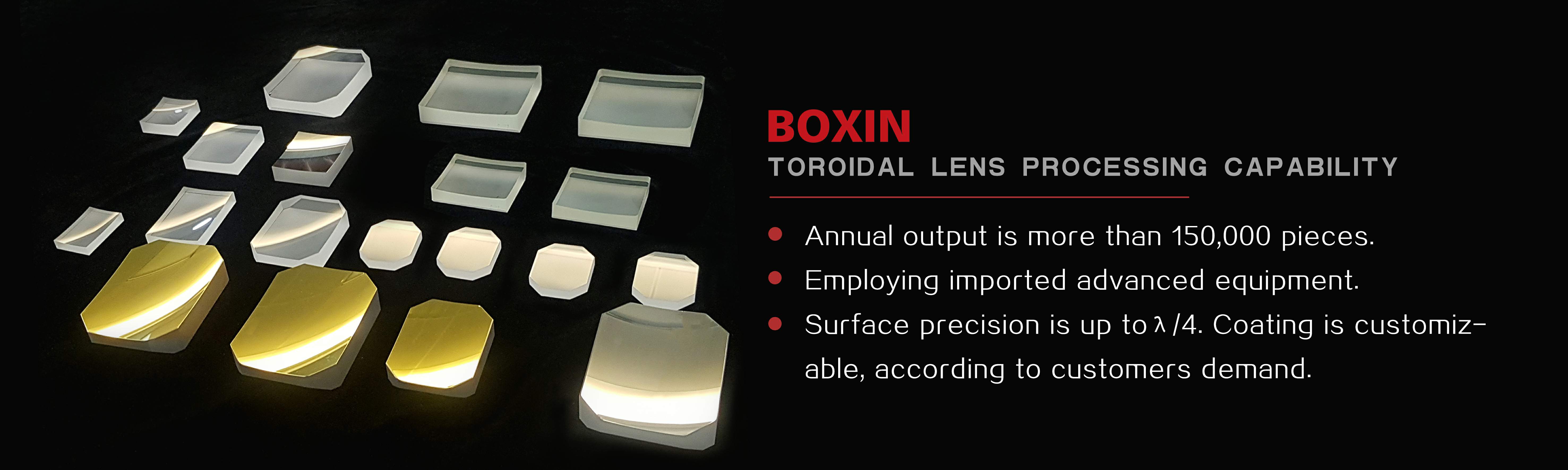

Toric Lenses Process Capability

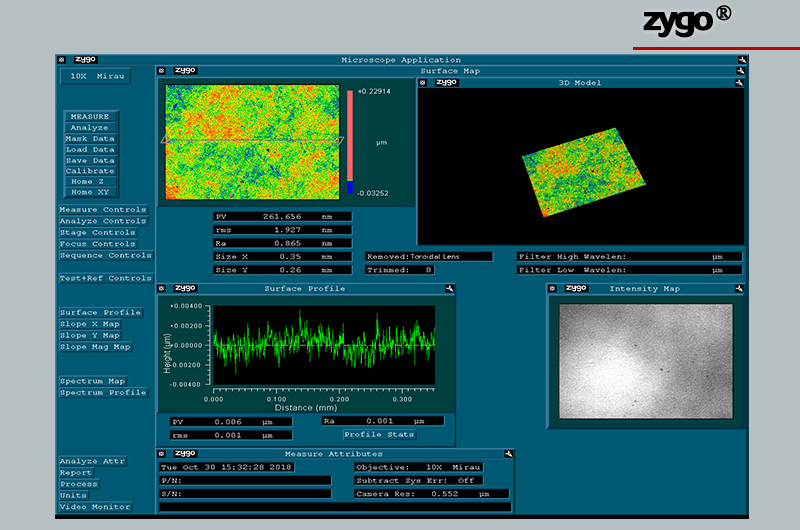

Boxin is equipped with 30 sets Toric Lens CNC Grinding and Polishing machines that imported from EU. We introduced Interferometer for accuracy inspection. For measuring data of special product we equipped Diffraction Lenses. We can process various materials. The process range from 10mm-300mm, and annual output is 150,000 pieces.

General Specification

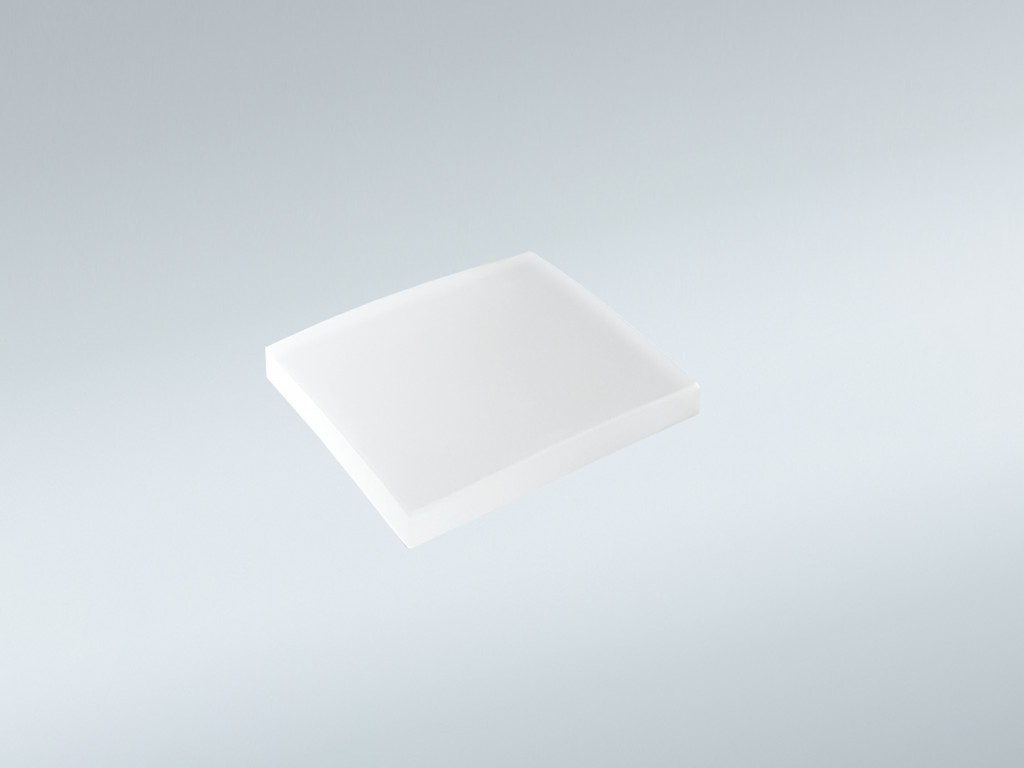

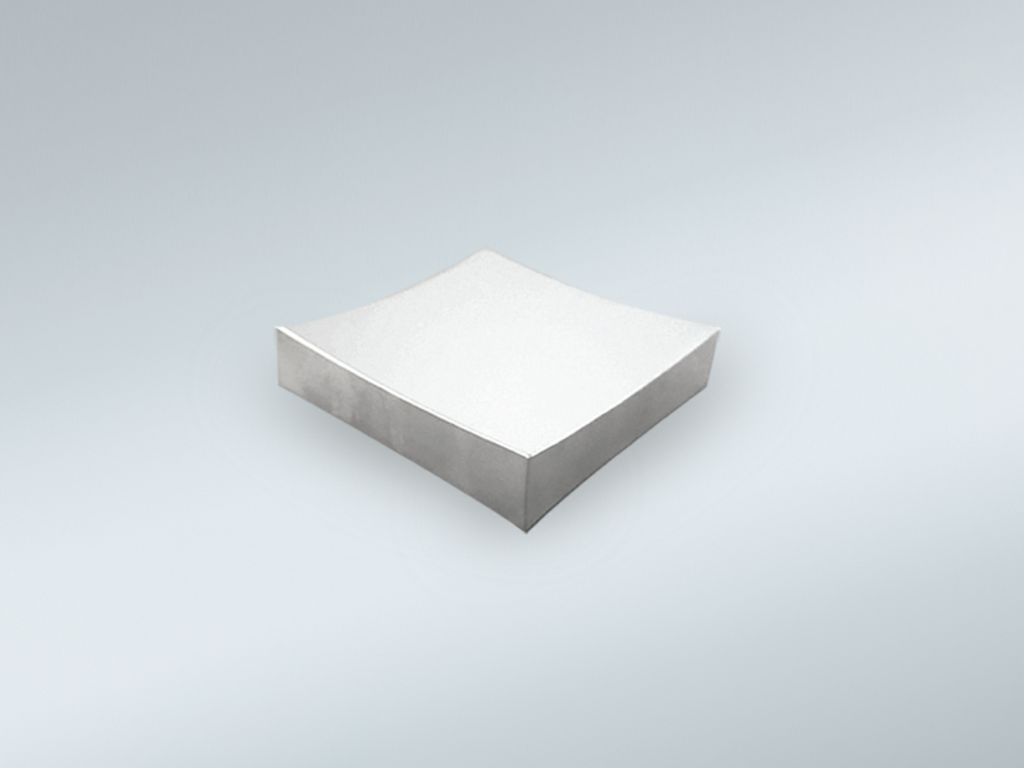

| Materials: Optical Glasses, Laser Crystal, Fused Silica, Radiation Resistant Glasses, IR & UV Materials, Metal Materials, e.g., SiO₂, CaF₂, BaF₂ etc. | Radius Range (mm): R30~R∞ |

| Dimension Range (mm): Φ10~Φ300 (Maximum processing size for non-circular toroidal lens : 300mm) | Dimension Tolerance (mm): ±0.01 ~±0.2 |

| Thickness Tolerance (mm): ±0.01 ~±0.2 | Scratch & Dig: 10/5~80/50 |

| PV: λ/4~λ/Φ100 mm | Centration: 30″~5′(or Δt ≤0.02) |

| Manufacturing Capability: Over 150,000 pieces/year | Coating: Customizable (For details, please refer to Boxin Optical Coating.) |

Boxin’s Toric Lenses Processing Equipment