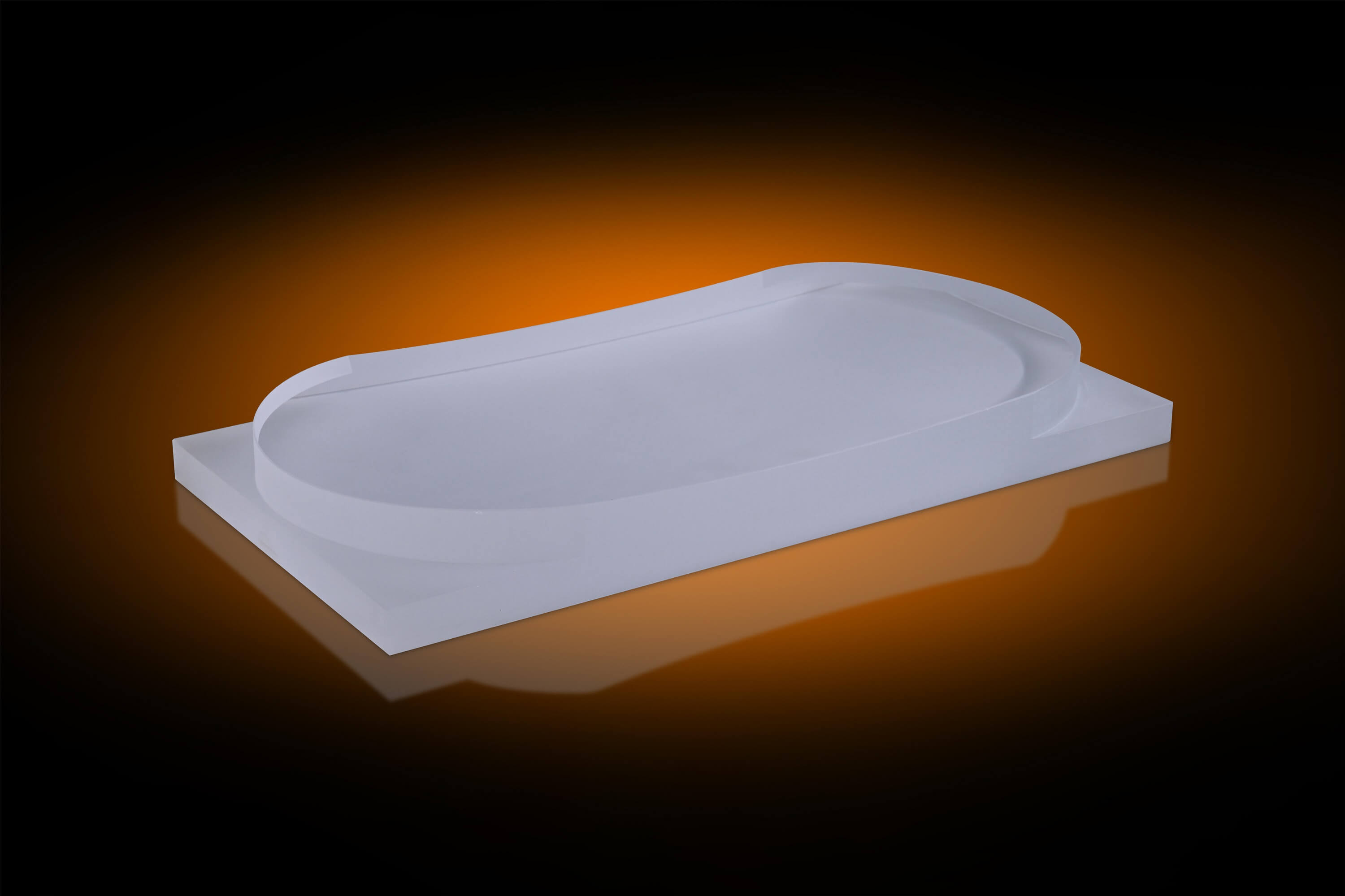

BOXIN is equipped with ion beam processing equipment for ultra-precision machining and ion beam etching of optical components. The equipment supports a variety of optical materials, including fused silica, microcrystalline glass, single crystal silicon, and sapphire. It is capable of processing a range of surface types, including flat, spherical, coaxial aspheric, off-axis aspheric, and freeform surfaces. The maximum processing diameter is 700mm, with a processing accuracy of up to RMS = 1/100λ and PV = 1/30λ. Surface roughness can reach Ra = 2-3nm.

BOXIN is also equipped with six-axis CNC machines for the precision grinding, rough polishing, and fine polishing of optical components. The equipment supports optical materials such as fused silica, microcrystalline glass, ULE, single crystal silicon, silicon carbide, and nickel-phosphorus alloys, and can process flat, spherical, coaxial aspheric, and off-axis aspheric surfaces. The maximum processing diameter is 1000mm, with surface form accuracy up to RMS = 1/70λ and surface roughness Ra = 2-3nm.

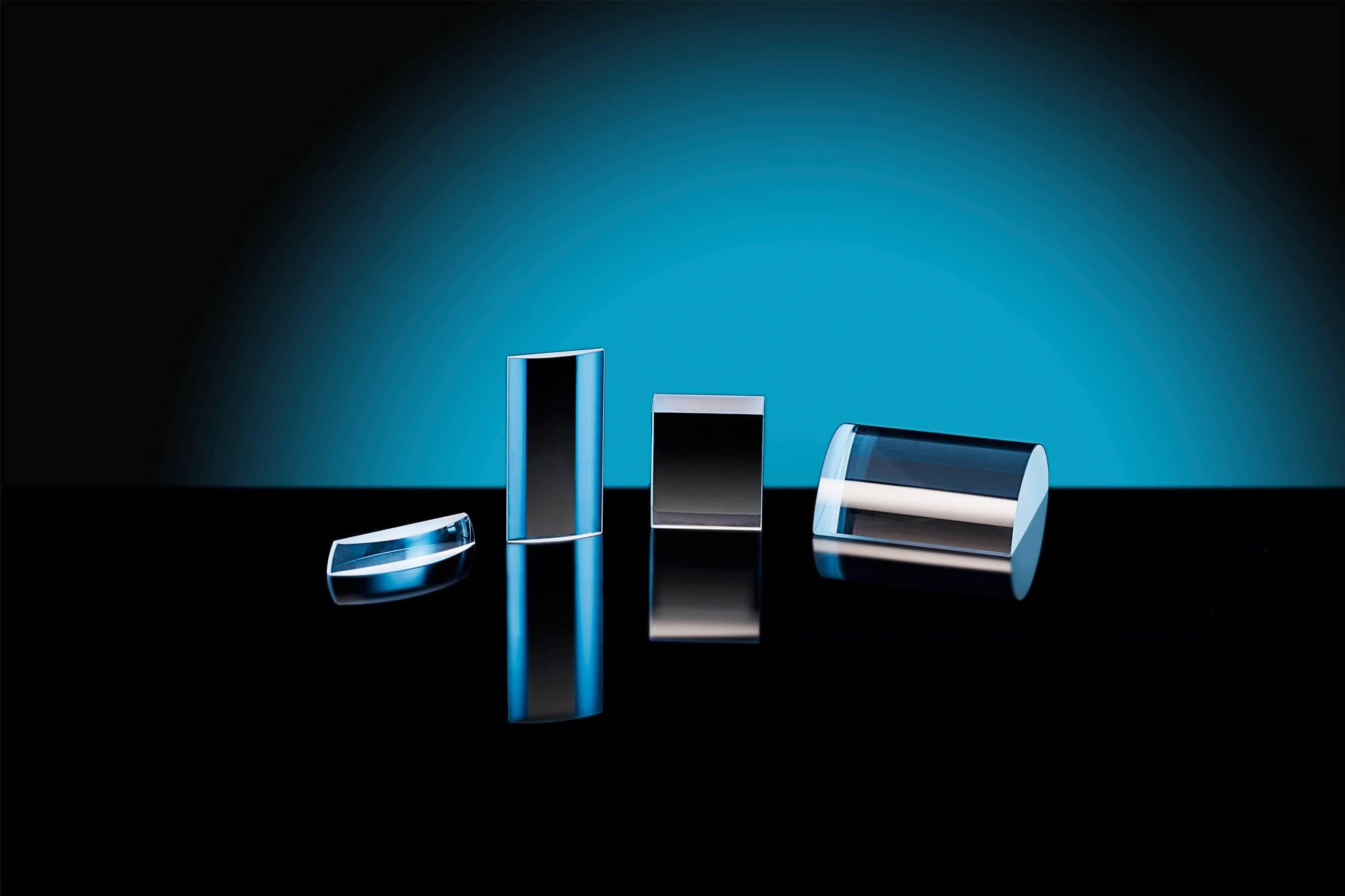

BOXIN's cylindrical lens workshop is equipped with over 100 polishing machines, CNC cylindrical lens milling machines, and polishing machines, as well as more than 40 traditional polishing machines. The annual production capacity for cylindrical lens products exceeds 2 million pieces.

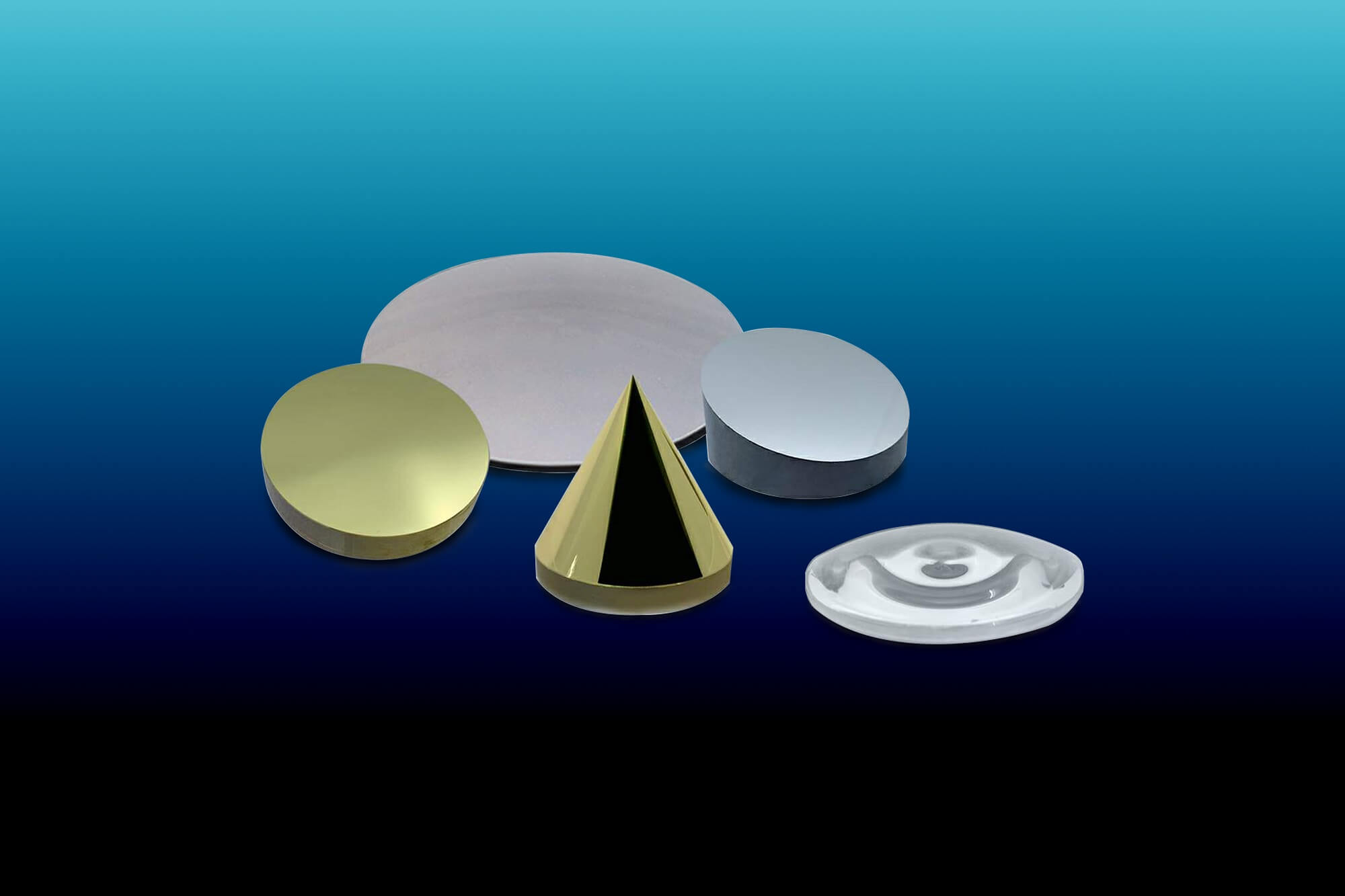

BOXIN's aspheric lens workshop is equipped with 5 Satisloh milling and polishing machines, and 8 self-developed aspheric lens milling and polishing machines. The annual production capacity for aspheric products is 50,000 pieces.

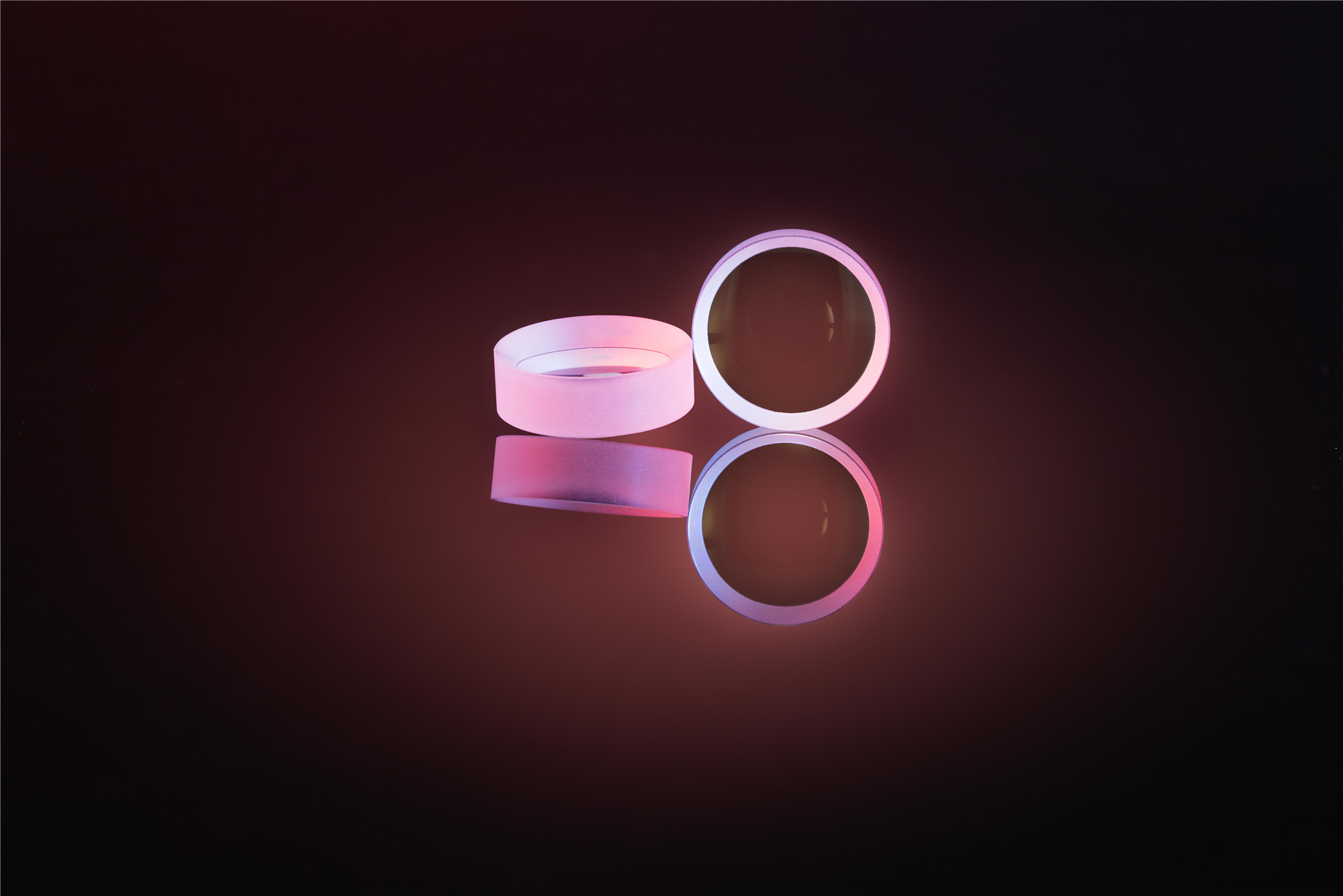

BOXIN's flat lens workshop is equipped with one CNC 800mm large flat milling machine, two 2000mm large ring polishing machines, three 1000mm separators, and eight double-sided polishing machines, providing reliable hardware facilities for the production of large-size flat products. The annual production capacity for flat products is 500,000 pieces.

BOXIN's toroidal lens workshop is equipped with over 30 European-imported milling and polishing machines. The annual production capacity for toroidal products exceeds 150,000 pieces.

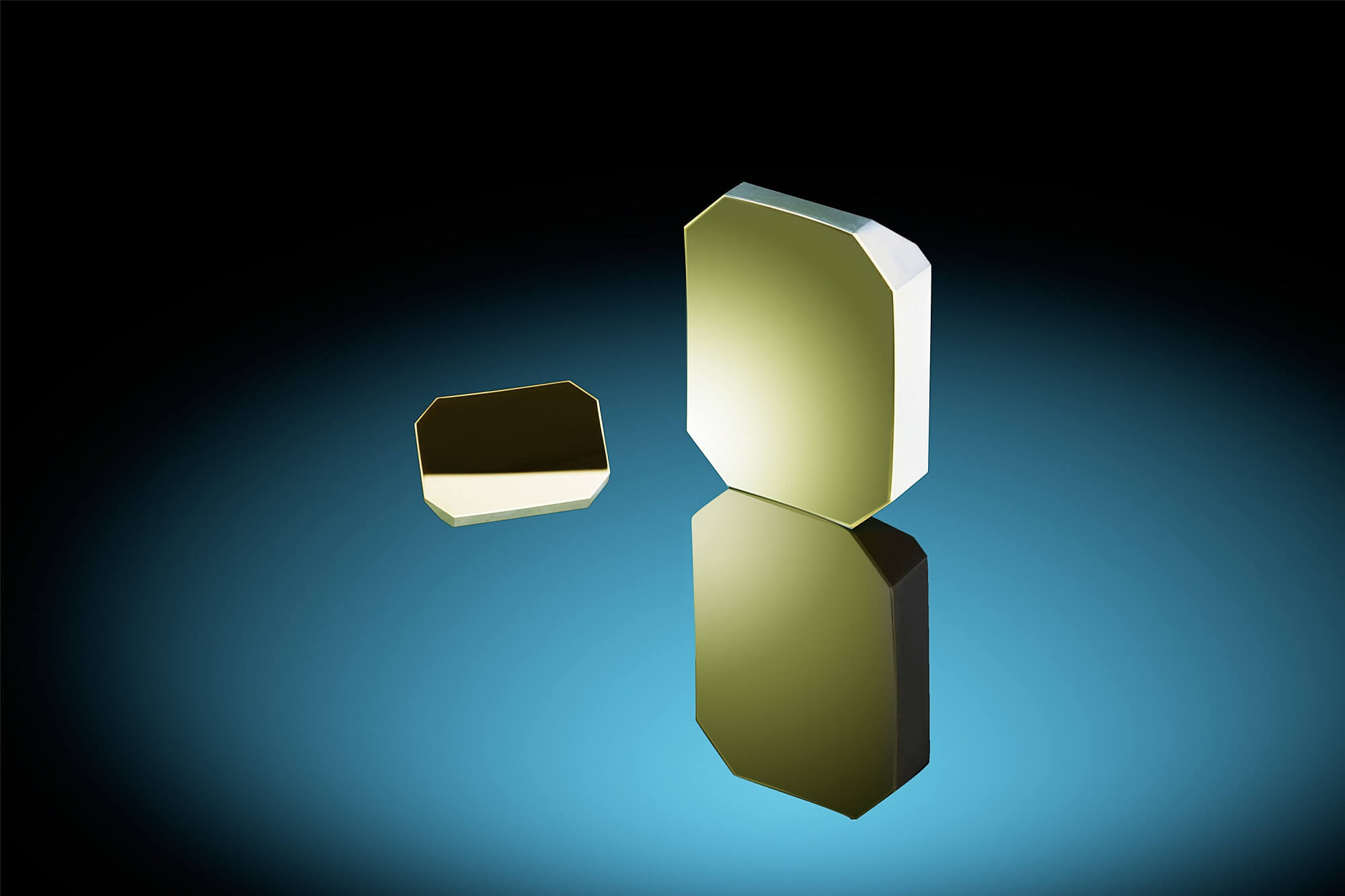

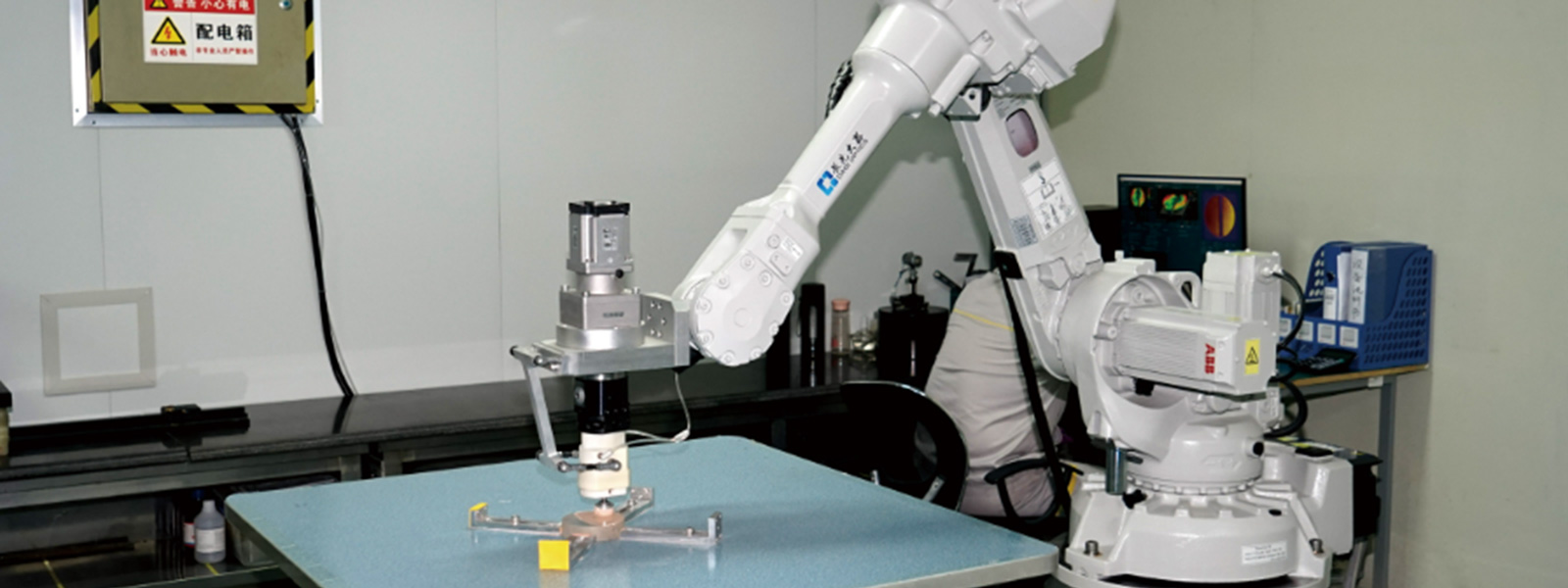

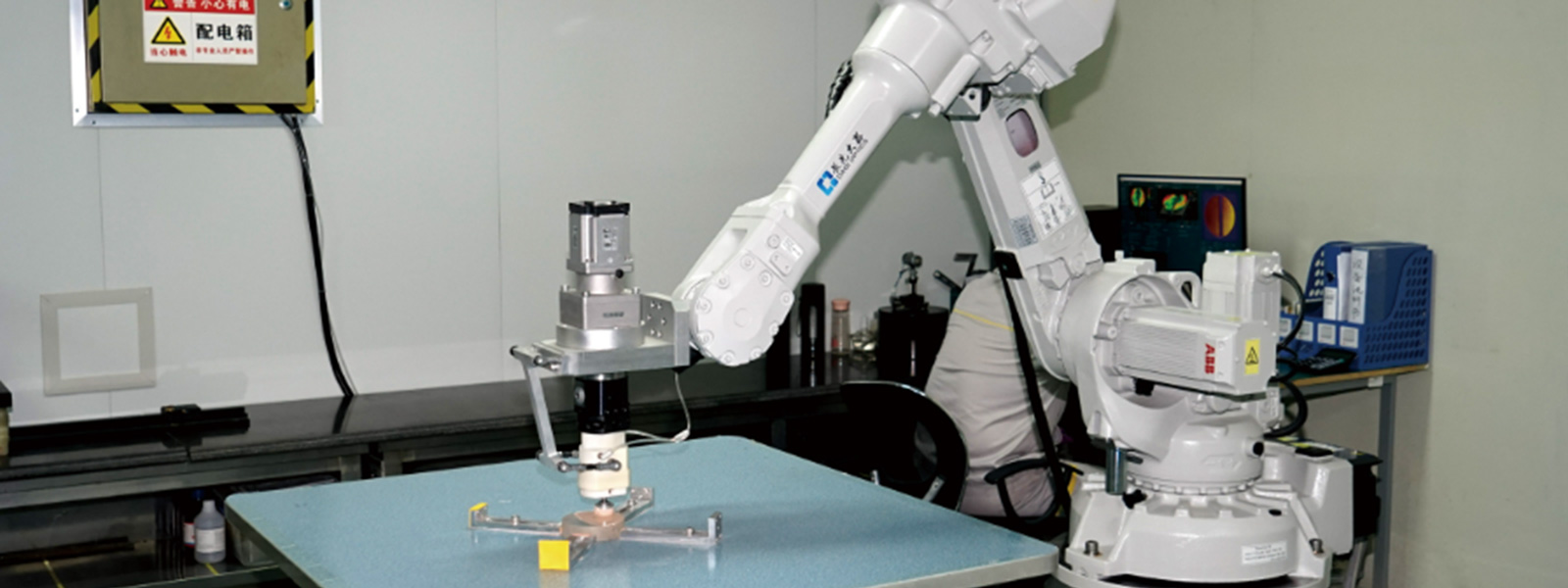

BOXIN is equipped with single-point diamond turning lathes capable of processing infrared products from materials such as aluminum, copper, germanium, or carbon-free crystals. It can process spherical, aspheric, and freeform shapes.

BOXIN's single-line glass cutting machine is capable of precision cutting optical components into various shapes. Our laser engraving machine is also workable on some varieties and thicknesses of glass materials.

Bosin has 9 machining centers and 5 fully automatic CNC lathes,self-made wire cutting equipment, as well as the shape processing equipment which self-upgraded by our machining center, we can handle deal with various shapes of optical parts, including squaring, rounding, irregular shaping, stepping, punching, bonding and so on.We can also make our own mould, tooling, fixture and other Machanicalparts.