Materials

Colorless optical glass, laser crystal, fused quartz, radiation-resistant glass, ultraviolet and infrared materials, metal materials, such as SiO₂, CaF₂, BaF₂, etc.Radius Range (mm)

R30~R∞Diameter Range (mm)

Φ10~Φ300 (maximum non-circular processing size: 300mm)Dimension Tolerance (mm)

±0.01~±0.2Thickness Tolerance (mm)

±0.01~±0.2Surface Quality (Scratch & Dig)

10/5~80/50Surface Accuracy

λ/4~λ/Φ100 mmCentration

30″~5′ (or Δt ≤0.01)Annual Capacity

Over 150,000 pcs/yearCoating Features

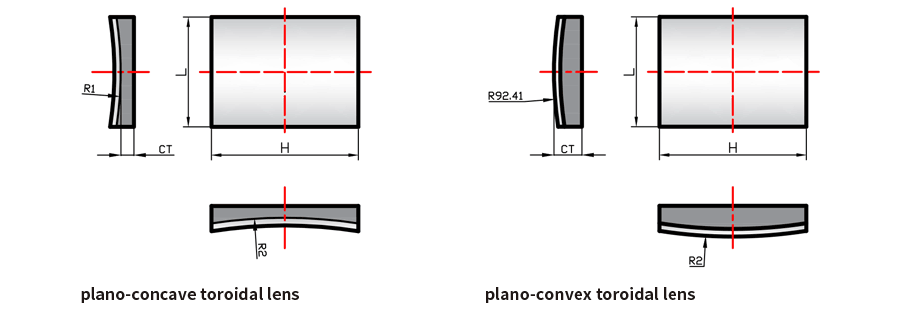

Customizable (refer to BOXIN's coating process types and layer descriptions)Toroidal lenses, also known as tire mirror or tire lenses, can be considered as an arc rotated around another arc along an axis. They are often used to replace optical lens groups, simplifying instrument structure and improving imaging quality. Toroidal mirrors do not cause image distortion like flat mirrors or single spherical mirrors, reducing the number of optical lenses required.

The company has over 30 European-imported toroidal lens milling and polishing machines. We have introduced Zygo interferometers for precision testing and have equipped diffraction lenses for measuring special product data. We can produce products using various materials for visible light and far-infrared applications. The production size range is 10mm-300mm, with an annual output exceeding 150,000 pieces.