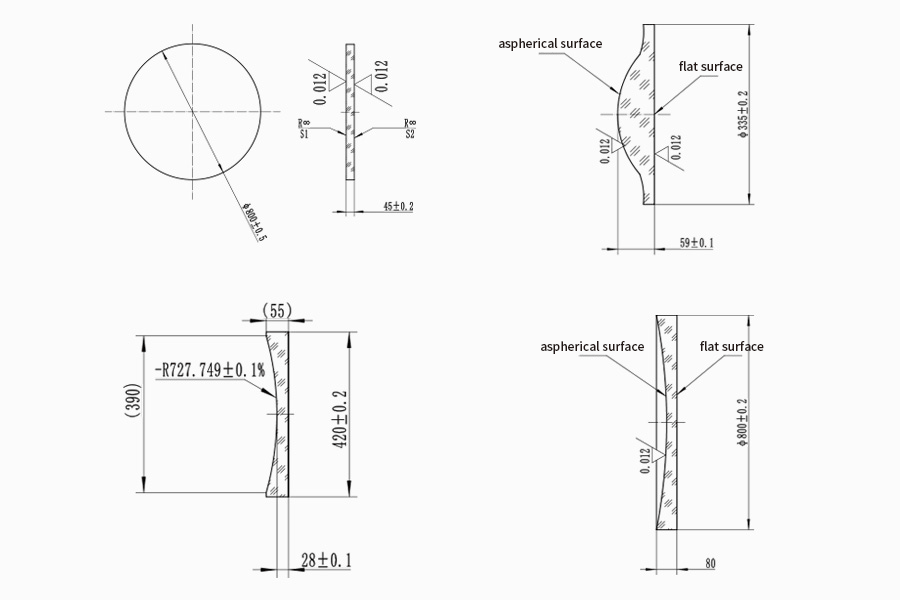

Materials

Colorless optical glass, colored optical glass, laser crystals, fused silica, radiation-resistant glass, UV and IR materials, metal materials, such as: glass-ceramics, Ge, etc.Maximum Processing Size for Large Aperture Flat Products

1200mmMaximum Processing Size for Large Aperture Spherical Mirrors

1100mmMaximum Processing Size for Large Aperture Cylindrical Mirrors

1200mmx650mmMaximum Processing Size for Large Aperture Toric Mirrors

300mmSurface Accuracy

λ/10/100mmCoating

Customized according to requirements (refer to Boxin Coating Process Types and Layer Introduction)The ultra-precision processing technology for large aperture optical components is a comprehensive application of new technological achievements from various disciplines, promoting the development of cutting-edge technologies in both civilian and scientific research fields. Driven by national optical engineering, Boxin's ultra-precision processing and production technology has significantly improved, especially in the ultra-precision optical cold processing of large aperture cylindrical components. On the existing rough grinding, fine grinding, and polishing process lines, Boxin has fully achieved high-precision batch production capabilities.

Large aperture optical components are mainly used in printing machinery, astronomical optics, high luminous flux systems, large field-of-view systems, long-distance imaging systems, scientific research, security, and defense. Boxin has 20 years of processing experience and four professional production lines for large aperture optical components, including: large aperture flat products, large aperture spherical mirrors, large aperture aspherical mirrors, and large aperture cylindrical mirrors. The maximum processing size can reach 1200mm, with surface accuracy of λ/10/100mm.